Have you ever decorated a toy racecar or dollhouse with a sheet of stickers?

Ordering components in groups or kits can simplify product assembly, saving you time and money. Customizable kits can improve product accuracy and inventory.

Depending on the product and application needs, Strouse ships specific orders in kits. When you’re using a combination of similar components on one product, you’ll want to consider the possibility of kitting.

Today, we’ll discuss the benefits of kitting in manufacturing that might help you prepare for your future production process.

What is the Kitting Process?

Kitting in manufacturing means building and supplying groups of products in one package to improve application and inventory. This is particularly relevant when you assemble your own widget or device and need a group of products for one widget.

Manufacturing kits offer better organization, pricing, and ease of application for masking or trim attachment applications.

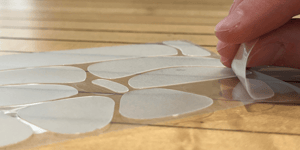

When it comes to flexible material converting, kitting involves using pre-cut shapes to cover, mask, pad, assemble, or decorate a surface. While masking is often done using rolls of tape, die cut parts have many speed and accuracy advantages.

KITTING OPTIONS

Manufacturing kits exist to simplify a single assembly line process, which is why they can be customized to fit your project’s needs. For instance, many businesses utilize multiple kits with slight variations to suit their different products.

Let’s say a client ordered a kit to mask car dashboards. One kit might contain Design 1, while the second kit used Design 2, another version of the adhesives. Kit variations might contain different shapes, colors, combinations, or additional parts.

4 Benefits of Kitting in Manufacturing

Not all projects warrant kitting, but many can benefit from it. If you’re interested in gathering similar part components for easier application, consider the advantages of kitting in manufacturing.

1) IMPROVED EFFICIENCY

Product application is one of the most critical yet underrated aspects of component manufacturing. You can consolidate multiple individual components into a single kit, making it quick and easy to grab the next part during assembly.

Masking kits contain adhesive tapes and film that fit onto particular spots without additional trimming. An action that could take minutes using a tape roll might only take seconds when you place a custom part where it’s intended.

2) HIGHER CONSISTENCY/REDUCED ERRORS

One of the most common mistakes you can make during masking is forgetting to block off a certain area of the object. However, this is far less likely to occur when using a kit.

Kits reduce your chances of losing or forgetting parts because they contain everything needed for application. The individual items correspond to a particular use, and once the kit is used up, the job is done. If a part is left over, your technician knows there’s something missing.

Additionally, most kits contain custom parts made to fit within specific tolerances, which helps ensure a consistent product look and performance.

3) KIT CUSTOMIZATION

In manufacturing, it’s crucial to consolidate and optimize processes most efficiently to save money. One way of doing this is by arranging the ideal organization of your components.

Working with multiple rolls of individual parts can require planning, which could result in a disproportionate amount of leftover components.

Certain components are often more challenging to apply than others. When you can customize the number of pieces you’re working with per application, you can decide how many spares you’ll need.

In addition, there are plenty of formatting options made easier by a kit, such as ordering sheeted parts over rolls or choosing to have certain components bagged before they come to you.

4) INVENTORY BENEFITS

Have you ever started cooking only to realize you were missing an ingredient?

Kits are a complete set of components with an easily trackable number of parts. Thanks to their consistency, you’ll never have to fear starting a project and running out of parts halfway through.

Storing rolls of product can be unwieldy, but storing kits can be as simple as stacking boxes. The extra packaging afforded to kits will also keep parts grouped together while protecting them from dust and moisture.

Kitting in Manufacturing Examples

Manufacturers often use kits to work on a singular product. For example, painting a vehicle might require a masking kit to protect the side mirrors, headlights, and other areas.

Using a kit will ensure clean, accurate lines and reduce the odds of accidentally forgetting to cover a particular feature.

In other cases, manufacturers might use adhesive kits to attach rubber protective or decorative accents to the vehicle’s edges. Each kit comes with exact quantities of different, custom-shaped adhesives.

Does Kitting Make Sense For You?

You may be wondering whether kitting suits your project. When you have an application with multiple similar parts grouped together, kitting is an excellent option for saving time and money.

If you’re interested in using assembly kits for your manufacturing process, consider scheduling a project consultation to discuss how it might benefit your finished product design and application process.

Otherwise, feel free to check out our Learning Center for more information on masking.

Originally published: October 17, 2023

%20(1)-min.png?width=290&name=Untitled%20(52)%20(1)-min.png)