Imagine sitting down for a tattoo, but the artist refuses to use a stencil because it’s ‘too expensive.’

“No way,” you’d say, “I want it done right.”

As a converter who’s spent years building parts for different masking applications, Strouse knows that die cutting masking tape can add a layer of consistency and efficiency to your production.

If you’re exploring the options for a masking job, you might consider using custom masking tape parts for the most structured and accurate application method.

Learning about how masking tape rolls compare to die cutting will help you understand your different options and ultimately decide on the best application choice for your project.

What are Masking Tape Kits?

Masking tape kits are an arrangement of different die cut adhesives used to mask a fixture during product assembly. They can contain parts in sheeted, rolled, bagged, or other forms.

For example, the masking tape kit for a car might include an assortment of adhesive tape parts cut in the shape of headlights, tail lights, blinkers, engine compartments, batteries, and wheels. Applying the adhesive tape parts to the car’s exterior would protect the masked surfaces from paint residue, and a masking tape kit would ensure all of the parts add up to cover a single vehicle.

Although you can order custom masking tape parts in singular, sheeted, or rolled form, using kits when applying similar parts to a single object is often more organized and efficient.

Why Do Manufacturers Use Masking Tape Kits?

Cutting out individual adhesive shapes takes significantly more time and lacks the accuracy of custom parts.

Masking tape kits contain accurate parts users can easily apply before painting. Each part is made with the same measurements and provides consistent coverage.

Typically, the masking process involves the user eyeballing their intended masking space and roughly cutting the shapes they need out of a long roll of material. Or even worse, they’re applying the tape and cutting it on the final product, risking damaging the product while cutting. However, this is not only an ergonomically unsound method due to hunching over for long periods, but manual masking also results in lower accuracy and more material waste from the application.

EASY APPLICATION

Compared to cutting out your own masking shape, which would typically take 2-3 minutes, custom masking tape enables you to only spend 10 seconds at most peeling the adhesive part off a liner.

Let’s say you had eight masking parts to apply. If one sheet contained all eight parts, you could tell whether you had missed any based on whether the sheet was empty during your quality check. However, if you used eight separate rolls with one part on them, you might lose track of what you already applied.

Re-painting a vehicle on account of failing to mask certain areas could be an expensive mistake. When using a masking tape kit to apply, you’ll know you’ve completed the job once the kit is empty.

In addition, custom sheeted and rolled parts often have tabs to facilitate easy removal after the paint has dried. You won’t have to worry about damaging surfaces or wasting time because the tab allows easy removal.

CONSISTENCY

Have you ever tried to draw a perfect circle? Try cutting one out of tape.

Even though you can cut out masking pieces, they’re unlikely to be as accurate in matching shapes. Also, if you cut the pieces by hand, each masking job will be slightly different and likely lead to more errors.

Custom masking tape parts match your exact measurements to fit around any object features. A CNC machine routes a die to match your shape perfectly. That die is then used to make your part over and over again with the consistency you need for your production. This takes out a risk of a lot of the errors you can see by doing it manually.

What are my Kitting Options?

Depending on what you need, we can design different kits to fit specific applications.

One product might require the masking parts 1, 2, and 3, while the other requires parts 1, 2, and 4. Upon your request, a converter could create two kits to match both projects and their needs.

Plus, if you find yourself using one part more frequently than the others, you can always request extra rolls of your more complex shapes just in case they tear so you don’t waste entire kits over small mistakes.

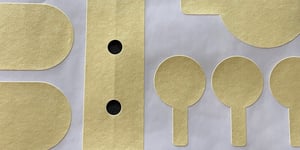

Another option is ordering mirrored versions of parts in the same kit, sheet, or roll. Mirrored parts are especially useful for retail use where both parts are used simultaneously, such as eyeliner stencils:

Masking Tape Kits vs. Manual Application

Masking tape kits are far quicker and more accurate than manual application, but this can come at an additional cost.

As mentioned before, custom masking tape parts usually require a die cut tool to build, which generates a die cut tooling cost. Depending on your project, this may or may not be worth the time you’ll save and the mistakes you’ll avoid during application.

Finally, it’s worth mentioning that while custom masking prevents users from wasting material during the part application, custom parts are still cut out from rolls of masking tape, generating waste during production.

Like the web left behind after peeling stickers off a sticker sheet, converters remove the surrounding material, leaving only your desired masking tape parts on the liner. The surrounding material is similar to scrap that you throw away when you cut out a shape by hand. The benefit of die cutting is you can usually quantify the scrap rather than guessing.

Should I Use a Masking Tape Kit for my Project?

Converters design masking tape kits for companies who use the same amount of parts on an object and can predict the exact quantities and extras they may need.

Instead of a masking tape kit, which comes with many different parts, other projects might benefit more from ordering sheeted or rolled parts.

If you’re still unsure about the cost of custom masking tape, or want to see whether kitting is an option for you, you can submit a quote with us:

Together, we can review the specifications of your product and how you plan on applying the masking tape so we can evaluate your potential options.

Looking for more info on masking? See our recommendations for the best types of masking tape.

%20(1)-min.png?width=290&name=Untitled%20(52)%20(1)-min.png)