You can only stare at material pricing pages before suppressing the urge to flip your desk.

Flexible materials are sold at an ever-shifting price point based on a range of factors. In the past, you’ve likely been left with the dreaded, technically correct answer about material pricing: it depends.

Don’t panic: I promise you that the cost of flexible materials doesn’t have to be a total enigma.

Strouse’s Estimators assemble quotes daily based on the rates we pay for our materials. You should know which factors affect your material pricing.

If you’re planning on purchasing a part made from flexible materials, read on for an explanation of what determines your material cost and how to work alongside a converter to solve material pricing concerns.

What Are Flexible Materials?

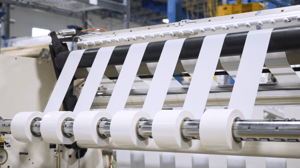

Flexible materials like tape, foil, and film are commonly used in adhesive manufacturing to create components like gaskets or labels. They also form bandages, transdermal patches, and many other products.

What Determines the Cost of Flexible Materials?

Like other manufacturing materials, the cost of flexible materials is ever-changing based on their availability and the type of material you need.

“[Flexible material converting] is a crazy industry… we don’t make different-sized donuts, it’s all custom.” —Dave Debus, Strouse Estimator

AVAILABILITY FACTOR

High demand can cause supply shortages and raise material prices. For instance, throughout the COVID-19 pandemic, it was tough to source certain materials because the demand grew suddenly.

While availability is a tough challenge to overcome, adjusting your order quantity can sometimes help you match bigger MOQs.

DIFFERENT MATERIAL PRICING FACTORS

Although it may seem obvious, the type of material and adhesive you use makes a colossal difference in how much you pay for the material.

You might ask, “But what if I need a specific material?”

This is where alternative materials come into play. Unless you need specific name-brand materials, you can discuss equivalents with a converter during the design and planning phase.

1. ADHESIVE TAPE

The price and MOQ of adhesive tape are highly dependent on the type of adhesive and vendor.

- Is the adhesive medical grade or industrial/conventional?

- What type of adhesive: acrylic, silicone, or rubber?

- All three have different pricing and availability.

- Is the adhesive a transfer or double-sided?

Your intended use determines the type of adhesive you choose, but as you’ll notice, every facet of these materials plays a part in the pricing.

2. FILMS

Film pricing depends on the film type, thickness, coatings, and chosen vendor.

- Is it polyester or polyimide?

- Polyester is usually cheaper than polyimide

- Will they come with adhesive?

Polystyrene, polycarbonate, and high-density polyethylene also have varying prices depending on where you get them.

You should also question whether the material needs to be coated or not. While print-friendly coatings help ink stick to a surface, and corona treatments facilitate stronger adhesive bonds, additional coatings and laminations add to the final price.

3. PAPER

Compared to other flexible materials, paper is relatively inexpensive.

- Are you looking for coated release liners?

- What type of coating do you need?

In addition to paper release liners, materials like paper label stock are often laminated to withstand outdoor elements, which adds to the final expense.

4. SOFT METALS OR FOILS

While soft metals and foils aren’t known for having a high MOQ, many come at a higher price.

- What are your required conductive/EMI shielding properties?

Each type of adhesive foil varies in use, but in terms of pricing, gold is predictably higher in cost.

5. FOAMS, PLASTICS, RUBBER

Foam, plastic, and rubber pricing depends on the different types, densities, durometers, colors, and more.

- Will the foam/plastic/rubber come with adhesive? If so, what type?

- Are we looking for sheets or rolls?

- The availability and price of each differs, especially with a distributor. However, a distributor might be necessary depending on the volume because some manufacturers only offer direct sales at higher volumes.

One thing you should know about foam is that suppliers often sell foam and plastics in high MOQs, which makes it more challenging to acquire manufacturing foam in low quantities.

Material Pricing Concerns and Options

Suppose you receive your estimated quote, but you’re unsatisfied with the price of materials. What are your options?

1. INCREASE YOUR VOLUME

Hear me out.

Material suppliers will oftentimes offer discounts when you buy more material at a given time.

If you’re converting your flexible materials, increasing your volume will decrease your price per part due to fixed costs to set up and break down the press. Lastly, the freight price will decrease proportionately if you place larger orders.

2. LOOK AT DISTRIBUTORS

Suppliers sell materials in bulk, but distributors will purchase said materials and sell them at a lower volume.

That is to say, when converters procure the material from a distributor rather than the manufacturer, they generally pay a higher cost/msi (mil-square inches) with a lower material order quantity (MOQ). If the MOQ is driving a higher total cost for your project, this can be an attractive option.

Seeking out a distributor is most suitable for small-volume jobs, and it’s worth knowing that your selection is limited with a distributor.

3. CONSIDER ALTERNATIVE MATERIALS

At the end of the day, some materials are just more expensive. However, you might be able to find cheaper materials that can still get the job done.

If you’re okay with trying alternative or equivalent materials based on your application, you might be able to reduce the material cost.

Are Flexible Materials From a Converter More Expensive?

You might be thinking, “Okay, I’ve done the math. Why do some materials cost more from a distributor than my local hardware store?”

The answer is simpler than you’d think: material formatting and minimum order quantities.

FORMATTING

The tape you get from the store is produced in bulk, allowing you to buy individual rolls. However, suppliers sell flexible materials in quantities large enough to be known as “logs” and formatted for manufacturing.

These material logs are useful during production because they reduce the amount of roll changes and wasted material, saving the customer money. If you try to then turn these larger rolls into smaller ones, the process isn’t as efficient as someone who always intended to create smaller rolls. This less-efficient process ends up costing you more.

MINIMUM ORDER QUANTITIES

As a non-distributor, Strouse doesn’t warehouse material, but rather uses what we ordered for the project at hand. Suppliers sell materials at specific quantities that determine the amount you need to purchase.

Let’s say you wanted to order five 10” rolls of a specific material from Strouse, but it only came in a log that was 50”. Perfect fit, right? Then, we discovered that the supplier only sold it in a minimum quantity of three logs. Now you have to buy fifteen rolls to get the five you wanted.

Something that may seem like a simple, small order could have a substantial minimum material purchase. That’s how the MOQ adds up.

How Can I Find the Right Flexible Material Value for My Product?

Whew! That was a lot of information, but now you’re an expert on the factors behind flexible material pricing. So, how can you utilize this knowledge to its fullest potential?

Firstly, you'll want to consider getting material samples. If you need a single roll of adhesive, consider talking to 3M or another supplier.

However, if you’re working on a project for a part component, you may want to reach out to Strouse so we can help ensure that the material fits your manufacturing process.

Material cost doesn’t stop at the price tag. Depending on your production process, the type of material you use could add expenses along the way. By consulting an experienced converter, you can avoid this risk by matching your material to the production method.

Want more information on material cost and converting? See our Learning Center for further resources.

%20(1)-min.png?width=290&name=Untitled%20(52)%20(1)-min.png)