When you’re working with painted metal and need to use an adhesive, rest assured that 3M’s 5952 adhesive tape is a solid choice.

You may wonder, “Out of these bazillion tapes on the market, how can I be sure that this one will work for my project?”

Our disappointing answer? You can’t. Not fully.

However, before you start testing different types, we’d like to demonstrate that the choice isn’t as complicated as others may make it seem.

Overview of 3M’s 5952 Adhesive Tape

Like many other 3M adhesive tapes, 5952 is a modified acrylic adhesive that can adhere two objects in a clean, durable manner.

3M’s 5952 adhesive tape has a flexible foam surface and a polyethylene film liner.

Its initial temperature resistance sits at 300 degrees Fahrenheit (149oC). However, during a long-term (a.k.a., days/weeks), 3M’s 5952 adhesive’s temperature resistance is only 250oF (121oC).

One important thing to note is the similarity between 3M’s 5952 and 4611 adhesive tapes, one used on painted metal, the other bare.

Also, as we’ll continue to discuss, the functionality of 3M’s 5952 adhesive allows surfaces to remain flat and pleasing to the eyes.

Applications

3M’s 5952 adhesive tape has many applications related to painted metal.

In fact, this adhesive appears to have been created for specialized use on powder-painted metal because its fraternal twin, 3M’s 4611 adhesive tape, is used on bare metal applications.

Although adhesive tape 4611 isn’t suitable for powder coat paint, 3M’s 5952 adhesive bonds with painted metal, plastics, and glass.

Here’s what 3M’s 5952 adhesive can bond with:

- Paints

- Powder coat

- Painted metal

- Composite panel

- Sealed

- Painted wood

- Metals

- Aluminum

- Steel

- Stainless

- Galvanized

- Plastics (HSE or MSE)

- ABS

- Acrylic

- Polycarbonate

- Nylon

- Plastics (LSE)

- Polypropylene

- Polyethylene

- Glass

- Wood

3M’s 5952 adhesive tape can bond and seal simultaneously.

Mechanical fasteners like bolts are known to cause distortion, splitting, or rusting issues, but 3M’s 5952 adhesive tape makes a perfect alternative to mechanical fasteners, which punch through and weaken the metal.

As a result, this adhesive is used for bonding and sealing plastic windows to pre-painted control panels, bonding large signs to their frame, and attaching logos/overlays.

Unlike bolting or spot welding techniques, the metal can remain strong, unmarred, and relatively untouched through the skillful use of powerful adhesives.

Adhesive tape like 3M’s 5952 allows you to work with thinner metal sheets without worrying about compromised structural integrity.

You can use thinner, more lightweight, and sometimes even less expensive materials because adhering doesn’t require a minimum thickness, unlike fastening or welding.

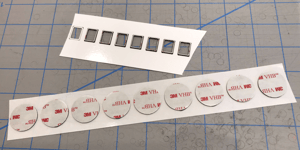

Adhesive tape also allows you to have your parts die cut, which might be a crucial step to increasing your company’s production time and overall efficiency.

Deciding if 3M’s 5952 Adhesive Tape Suits YOU

If you’re looking to solve a problem that includes adhering something to painted metal, 3M’s 5952 adhesive tape is an excellent option.

Other factors, such as selecting an adhesive tape to prevent galvanic corrosion, may also play a role. 3M’s 5952 adhesive provides a film barrier between different metals to stop bimetallic decay, which might come in handy in certain circumstances.

The application process is smooth compared to liquid adhesive and eliminates its gooey, sticky mess and curing delay. However, while 3M’s 5952 adhesive tape is much easier to apply than its liquid contemporaries, it does cost quite a bit more.

If cost is your ultimate make-or-break, this could be your cue to exit stage left. However, adhesive bond strength is crucial to the quality and health of your products.

With liquid adhesives, inexperienced users might misjudge the amount needed and add too little or even too much epoxy, which can result in damaging connecting parts. In addition, too much adhesive could result in an unsightly appearance due to overflow.

Again, if quality and efficiency are your top goals, you should figure out how to fit actual die cut adhesives into your budget. Plus, if you have any questions about how to go about it, you can send us a message.

Strouse has decades of experience, and we’d be happy to help figure out your next move.

Choose the adhesive that works best for your project and leave the rest in the shopping cart. When in doubt, don’t hesitate to experiment and see which option gives your design the best options.

%20(1)-min.png?width=290&name=Untitled%20(52)%20(1)-min.png)