Suppose you’re a nurse attempting to secure a bandage at a hospital, but when you turn around, there’s only a massive 10-foot log of gauze.

Material suppliers love generating bulk orders because buying in bulk is more cost-efficient. However, these jumbo rolls of material aren’t efficient in everyday use and can cause problems for businesses trying to use them for production. Precision slitting allows you to have custom-width rolls that are easier and more efficient to use.

As a converter that orders most of our own material in logs, Strouse has extensive experience with each roll slitting method. Each slitting method gives you a slightly different final result in cost and appearance, which is why you should understand the difference between roll slitting services.

Once you learn about the types of roll slitting services, you’ll be ready to make the right decision for your project to create your ideal end result.

What Are the Types of Roll Slitting Methods?

There are two types of roll slitting methods at a high level: log slitting and rewind slitting.

1. LOG SLITTING

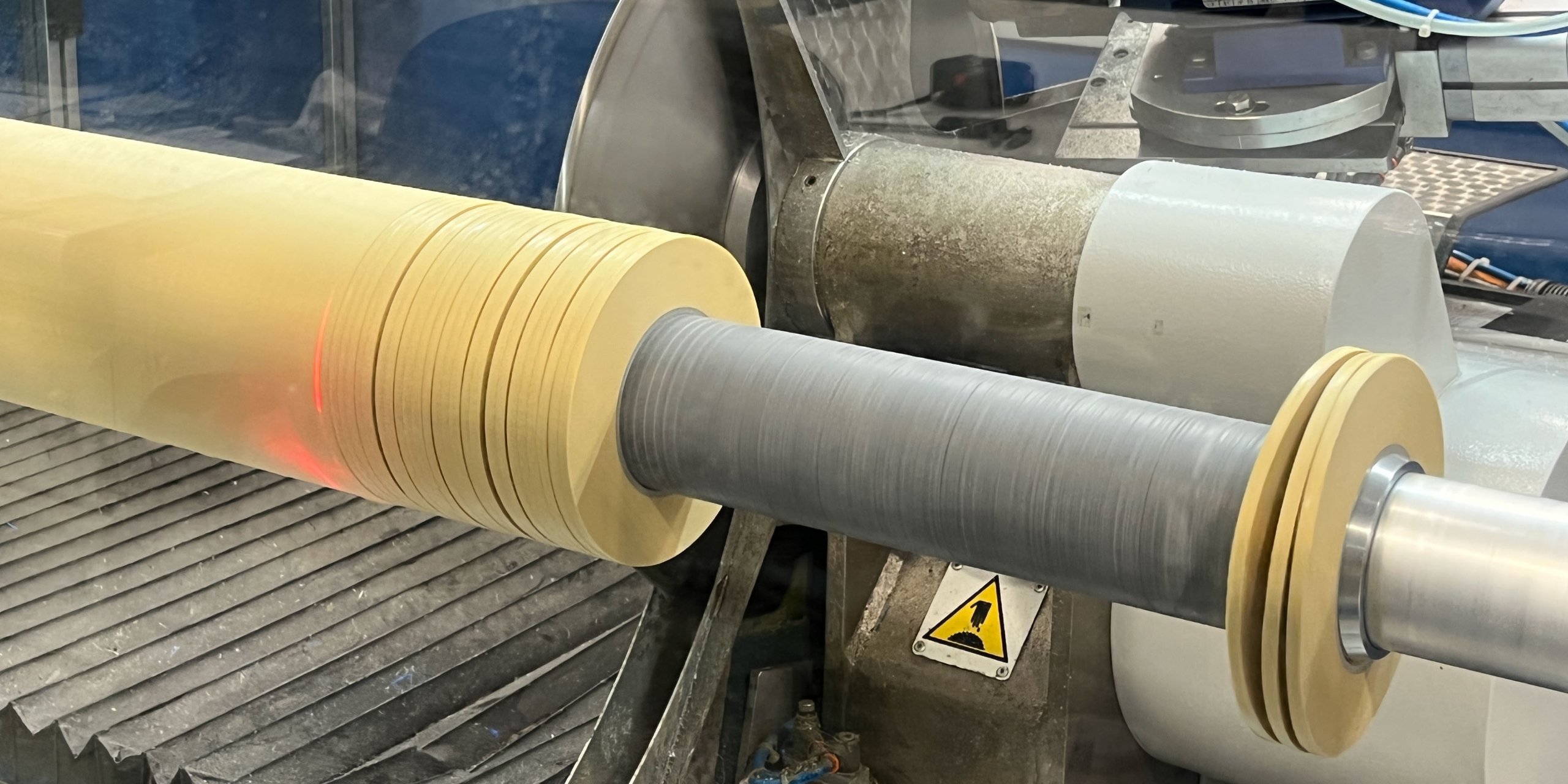

Log slitting involves chopping huge rolls of material into smaller rolls (think bologna slicer at a deli). After mounting a log of material onto a steel roll, also called the “anvil roll,” converters use a rotating knife to slice the material.

Log slitting requires less setup, making it generally faster than other slitting methods. However, it does have limitations regarding material width and constraints on thickness and tension.

2. REWIND SLITTING

Rewind slitting is the process of slicing singular layers of material rather than rolls and comprises three different methods:

- Shear slitting

- Razor blade slitting

- Score slitting (crush slitting)

Each rewind method can be standalone or built into an in-line process on a rotary machine press. Rewind slitting is more versatile due to the range of options and can achieve tighter tolerances.

Strouse performs both log and rewind slitting. Today, we’ll dive into the different types of rewind slitting methods so you’re prepared to choose the right services based on your slitting options.

What Are the Types of Rewind Roll Slitting Methods?

As mentioned above, there are three types of rewind roll slitting methods: shear, razor, and score slitting.

Each roll slitting service can either be conducted independently by slitting large material rolls into smaller rolls OR integrated into a more extensive project process, like feeding a log of material into one end and receiving stacks of finished die cut parts to maintain a one-pass production process.

a. SHEAR SLITTING

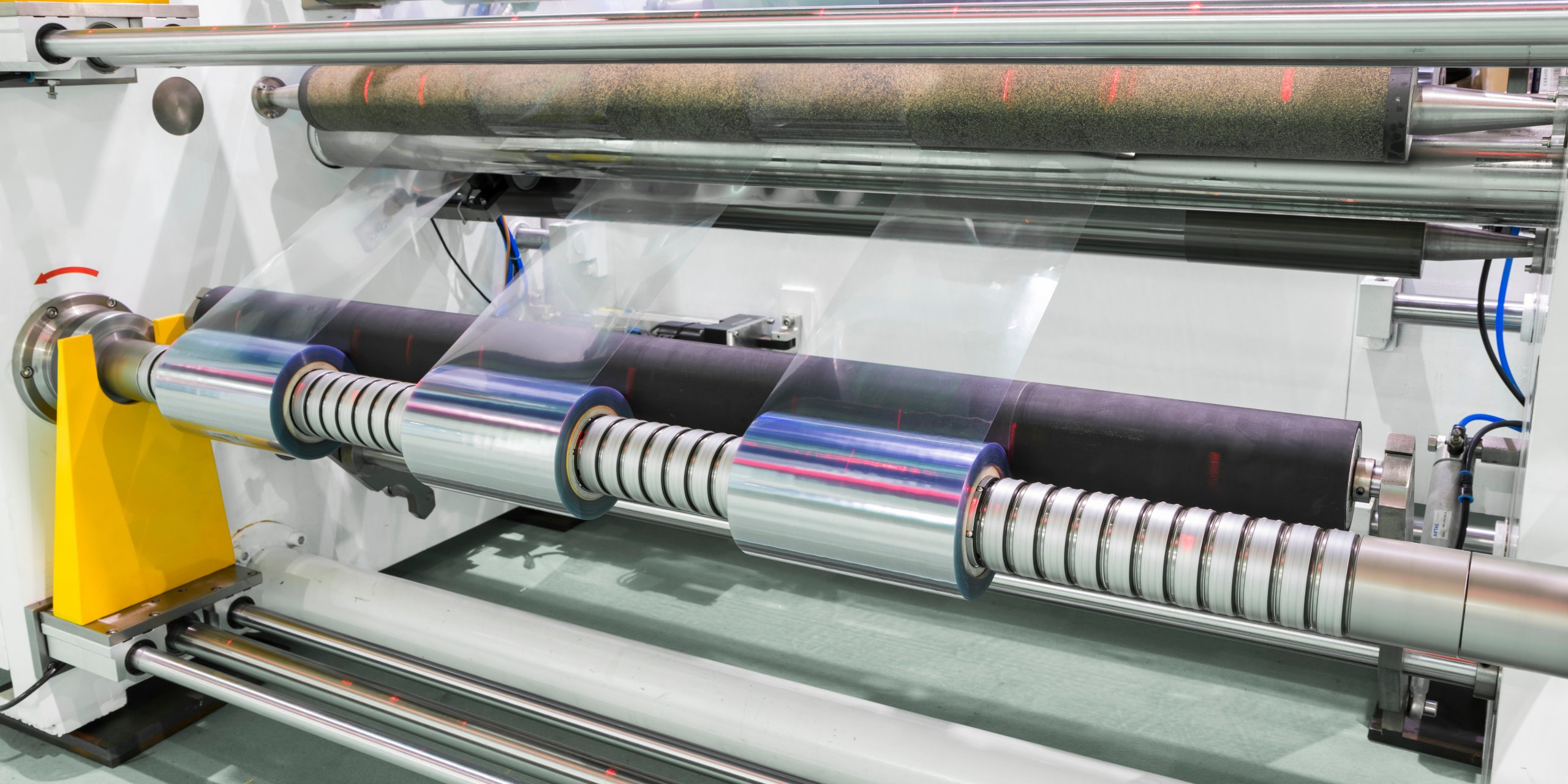

Shear slitting uses circular “male and female” knives that interlock to create a scissor-like cutting motion.

First, the material is wrapped around a rotating die and fed between the blades to create a sustained cutting process. Then, it travels through the press in different, smaller paths until it’s re-rolled into multiple, smaller rolls or used in a project process.

Converters can shear material at relatively high speeds, creating less residue and avoiding common slitting issues like feathering. Yet, because shear slitting requires a set of circular knives, it can be a more costly slitting method.

b. RAZOR BLADE SLITTING

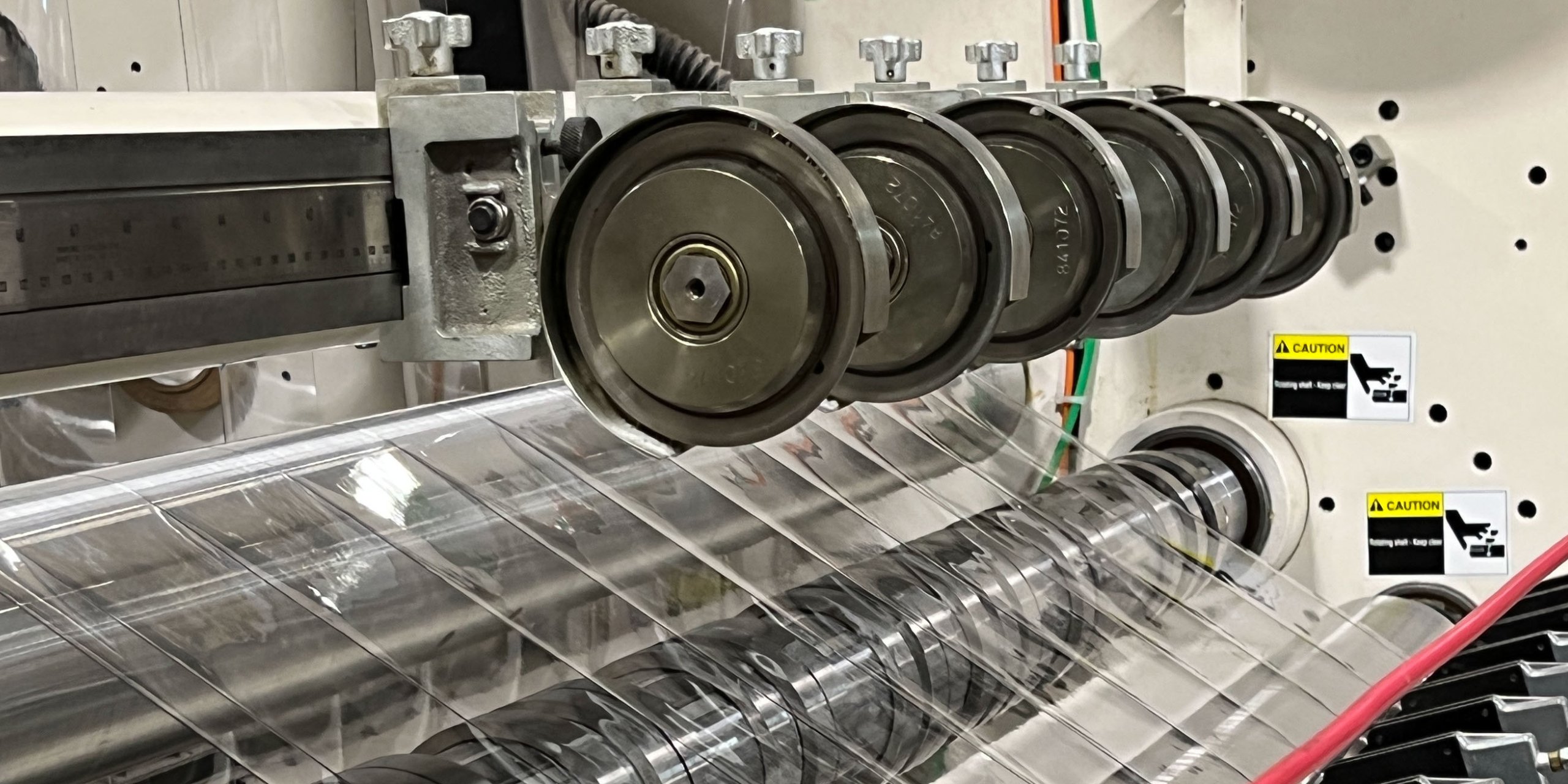

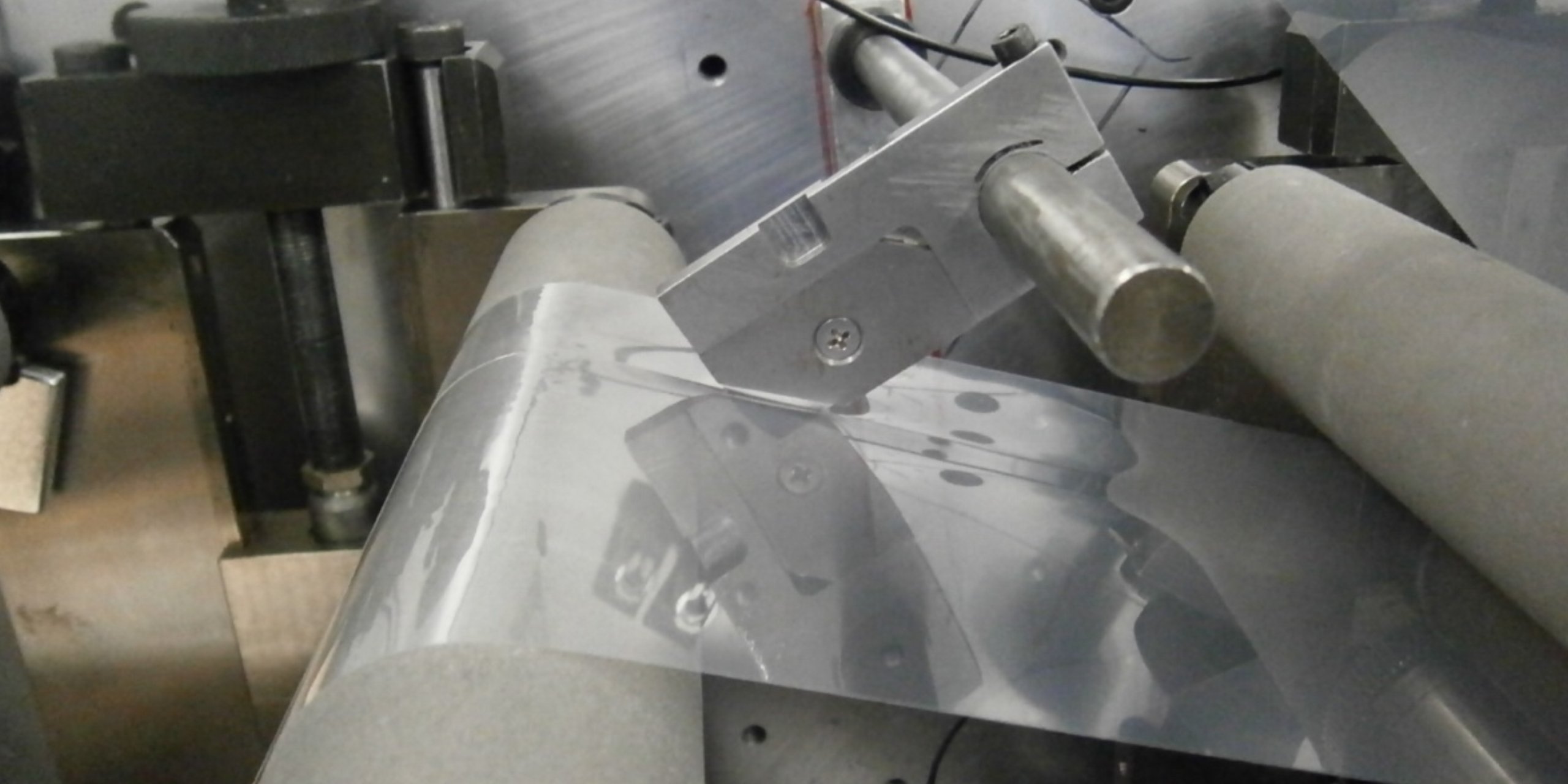

Razor blade slitting occurs when a stream of material is fed into razor blades at a precise angle. This process can be done without (razor-in-air) and with support (razor-in-groove), which involves placing a grooved metal below the material to support jobs running at a higher speed for smoother and more accurate cuts at the price of a longer setup time.

Due to the inexpensive blades, razor blade slitting is the least costly roll slitting method. However, when the material runs through the razor blades, it creates debris and feathery pieces that are sub-optimal for projects with medical applications.

Razor blades also cannot hold close slitting tolerances and won’t cut through rigid or abrasive materials.

c. SCORE SLITTING (CRUSH CUT SLITTING)

Unlike shear and razor blade slitting, score slitting is often performed directly on the roll of material.

Converters divide large material rolls with score slitting by pressing rotating knives against the material. They place material over an anvil roll and set up rotating knives to slice through the material and core in the desired intervals.

Score slitting is very quick to set up, which reduces labor costs, but it might create dust and rupture the materials’ smooth edges, making them look and feel rough.

Which Type of Roll Slitting Service Should I Choose?

The roll slitting service you choose depends on the material you’re using, your project budget, and your desired result.

Material is the most crucial consideration when choosing a roll slitting service because certain materials are more likely to fray or be challenging to cut. Plus, the material thickness can play a prominent role in the difficulty of roll slitting a material.

LOG SLITTING VS REWIND SLITTING

If you’re deciding between log slitting and rewind slitting, remember the differences in speed and accuracy. Log slitting has an easier setup time, but it is limited by material types and tolerances.

Rewind slitting offers a range of different options, but each takes longer to set up because it's cut in line.

Razor blade slitting is recommended for jobs using light and non-abrasive materials. On the other hand, score slitting is ideal for paper pressure-sensitive tapes because it creates the desired separation between the paper web, and shear slitting is more likely to create a smooth, clean finish.

When you work with an experienced converter, they’ll already know how your material behaves when roll slitting. If you’re still considering which roll slitting method to use, consider reading more about the different services or discussing your project with a converter.

Your project budget is also a consideration when choosing a roll slitting service. The cost of roll slitting can vary depending on the process you choose, so you’ll want to consider whether you’re willing to pay more for the result.

Reach out to get a quote today or discover more information on roll slitting in our Learning Center.

Originally published: April 27, 2023

%20(1)-min.png?width=290&name=Untitled%20(52)%20(1)-min.png)