Think about it this way: some customers order a seasonal white mocha frappuccino with two pumps of vanilla cream plus caramel drizzle on top, while others order “a cup of coffee.”

Like any coffee shop, the cost of your die cut parts increases along with the complexity of your order. However, it isn’t always apparent to the customer why certain designs lead to more costly projects.

For each new design we receive, Strouse plans a custom operation on our machines. Yet, the differences in die cut designs cause production to vary in price depending on the difficulty of certain manufacturing aspects.

Rather than getting caught off guard by an expensive quote, you can prepare for your design plan by learning about the difference between simple and complex die cut pricing and how to optimize your part for the lowest functional cost.

Which Design Factors Influence the Cost of My Die Cut Parts?

You might struggle to understand how your part is expensive when it looks simple on paper, but in reality, your converter spends ample time figuring out how to run it on the machine press.

Although it can be difficult to recognize whether you have a complex design, certain factors, like a large number of layers or tight die cut tolerances, will increase the risk of your design becoming expensive to construct.

TIGHTER DIE CUT TOLERANCES

Die cut tolerances are the acceptable margin of error for any given measurement.

Flexible tolerances cause the sizing of your part to fluctuate slightly between units, but they’ll also save you money. Alternatively, die cut parts with tight tolerances can be nearly identical at a much higher cost.

Parts with tighter die cut tolerances are more challenging to manufacture for multiple reasons:

- Firstly, the machine press may take longer to set up due to adjustments, leading to an increased labor time cost.

- Secondly, the quality check must be rigorous, which could require additional time or equipment.

- Thirdly, the die cut tool will be more intricate to build, possibly requiring multiple die cut tools or higher caliber steel, depending on the design and material.

In short, tighter tolerances can add to your labor time and increase the cost of tooling or quality testing equipment. Tightening your die cut tolerances might transform a relatively simple part design into a complicated and costly venture.

ADDITIONAL DIE CUT FEATURES AND PROCESSES

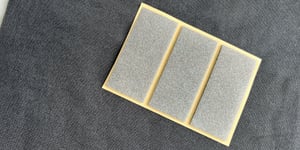

Additional features increase part functionality but add to the complexity of your machine process and design. Simple die cuts possess minimal layers and features, whereas complex designs often have additional features and processes like tabs, printed layers, and lamination.

As a standalone process, adhesive lamination might be relatively simple, but running many different layers among other operations on a machine press risks will increase your part’s price.

Tabs can reduce application time, but adding a tab could require new die cut tooling. Printed layers can provide essential information, like instructions on product usage, but you’ll need to source ink and match it with the type of material you’re using.

Remember that adding features or processes to your design is ideally done earlier rather than later in the design process. Discussing features upon the initial request allows your converter to build the production process around your specifications. Waiting can lead to costly re-designs due to changes in your operation planning process.

How is Die Cut Cost Affected by the Complexity of My Designs?

The more complicated your design, the more your die cut parts will cost. But which factors does the design impact, and how?

Material selection, the cost of tooling, and machine tolerances are all impacted by design complexity. Understanding how these factors are affected will explain why your price increases based on choices in design.

1. DIE CUT MATERIAL SELECTION

Out of all the flexible materials your converter can die cut, some are easier to cut than others. In fact, there are hidden costs in cutting semi-rigid, elastic, or otherwise hard-to-cut materials on a machine press.

Foams, elastics, or metallic materials are often harder to cut with absolute precision, meaning it might be a lengthier process with added waste due to how the material behaves on a press. Whether it’s thick, stretchy, or abrasive, your material selection can complicate the cutting process.

Any material that makes your tolerances more difficult to reach could increase your production cost, a risk you’ll want to know about during the material selection process.

2. PRICE OF DIE CUT TOOLING

Every part design produced on a rotary die cut press requires a unique tool, and complex part designs lead to more expensive tooling. Because of this, the price of die cut tooling varies considerably.

Hard-to-cut materials, multi-layer products, and tighter tolerances can all contribute to pricier tooling. Some materials require blades of a specific quality and angle that require highly customized tooling and may need replacing more often. Multi-layer products sometimes require multiple die cut tools, and tighter tolerance tools are more difficult to construct accurately.

Your tooling cost depends on your material, your design, and the strictness of your tolerances, but it also depends on the intended lifespan and quantity of your process. Is this a one-time production, or do you intend to continue this project over a series of months, or years? Keep in mind that die cut tools are bound to wear out eventually, and for complex designs, you’ll want to opt for a durable tool so it doesn’t need to be replaced as often.

How Can I Get the Best Die Cut Cost with My Design?

Finding the best die cut cost isn’t always about leading with your most simple design, but rather collaborating with your converter to make changes like consolidating layers or loosening tolerances when possible to make your design highly manufacturable.

Of course, design optimization also depends on part functionality, so your fully-optimized part could have more or fewer features depending on your goals. There’s a balance to be had between lowering your cost per part and your total production cost. Sometimes, making a part simpler will increase the complexity of assembling, which will net a higher cost overall.

This conundrum is why it is so important to discuss your application with your converter.

Die cut costs can be confusing, but you can read a more extensive guide if you’re looking to learn more about die cut pricing:

%20(1)-min.png?width=290&name=Untitled%20(52)%20(1)-min.png)