The estimated global hydrogel market size was US $2.7 billion in 2021: Within one year, it was forecasted to increase by over $1.2 billion.

We’ve come a long way from the original glass (yes, they were glass) contact lenses, and hydrogel has gained rapid traction as a wound care solution.

Strouse has processed hydrogel for modern wound dressing applications and as a flexible material inside medical devices.

If you’re debating if you should buy hydrogel, consider your options by reading about the different types of hydrogel, the price, and other factors that’ll prove whether it’s right for you.

Different Types of Hydrogel

Burn wounds can feel excruciating, but sometimes the skin is too sensitive to withstand cold running water. Hydrogel reduces severe pain by creating a cooling sensation that soothes the skin.

These wounds are all often treated with hydrogel:

- Scrapes/scratches

- Minor burns

- Chronic wounds

- Wound cavities

- Surgical and post-operative wounds

Two forms of hydrogel are used in clinical settings: Sheet and amorphous hydrogel, which essentially serve the same function in hydrogel applications despite having different physical structures.

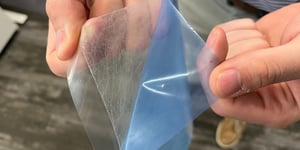

Sheet hydrogel is a solid patty of hydrogel placed on top of a shallow wound. Secondary bandages aren’t necessary to fix sheet hydrogel, but because hydrogel lacks sticking ability, it’s safer to cover rather than to risk it falling off.

Amorphous hydrogel is a liquid packaged in spray bottles or tubes and can be applied either soaked onto gauze or directly into a wound cavity. Their deformable nature makes amorphous hydrogels ideal for pressure-sensitive wounds vulnerable to further skin trauma.

While amorphous hydrogels can effectively pack and heal severe pressure ulcers with a longer lifespan than saline dressings, they’re often changed within two days.

You can choose a sheet or amorphous hydrogel depending on the wound depth and shape, but regardless of the type you select, let’s go over the four questions you’ll want to ask if you’re considering a hydrogel purchase.

4 Questions to Ask Before Buying Hydrogel

Hydrogel is a unique material that might not suit your needs.

Instead of trying to sell you on the idea of hydrogel, these questions will serve as tools as you research to determine whether hydrogel is the correct material for your intended applications.

#1: WHAT ARE THE BENEFITS OF USING HYDROGEL OVER OTHER SOLUTIONS?

Traditional wound dressings use gauze to absorb moisture from the wound bed.

By building a scab over the wound, your body tries to heal itself from burns, cuts, and minor abrasions. Dry bandages can end up scabbing into the wound, making it painful and damaging to remove.

You also might’ve noticed that healing scabs can take days or even weeks.

Softening scabs by moisturizing them is an age-old method to heal them faster. When done correctly, preventing a scab will promote epithelialization.

Hydrogel aids in healing by maintaining the dynamic moisture balance of the injury. It moistens the wound to prevent scabs from forming, ultimately speeding up the healing process.

In addition, the moist environment created by hydrogel dressings soothes and protects nerve endings from suffering further irritation or damage.

Although hydrogel dressings are a highly effective solution for wound care, they can be an expensive and laborious material to process. Before you check out the suppliers mentioned further on in this article, make sure you consider the potential problems that can arise from running hydrogel on a die cut press.

#2: WHAT ARE THE MOST COMMON HYDROGEL CONVERTING PROBLEMS?

Working with hydrogel isn’t all fun and games– If it were, everyone would do it!

Hydrogel is a tricky and uncommon substance to handle. Plus, various issues can arise during hydrogel processing. We’ve made you a list of the most common hydrogel problems you or your converter could encounter:

- Drying out

By far, one of the most common issues with processing hydrogel is ensuring it doesn’t dry out.

Hydrogel is composed of 90% water with a gel base made from gelatin, pectin, polyvinyl, or polyethylene. It has a short lifespan when exposed to air and requires proper care to ensure that the hydrogel doesn’t dry up during storage, processing, packaging, or shipping.

- Difficult to handle

Imagine somebody handing you a strip of chewed bubble gum and asking you to cut a shape out of it. After you get over the appalling gift, you would be stumped to figure out how to accomplish the task. That’s the struggle equivalent of processing hydrogel. Your converter is tasked with transforming this strange, stretchy, goo sheet into a die cut part.

While cutting hydrogel into precise shapes is possible, it’s also a complicated task that requires a complex machine setup. The set-up for hydrogel is a difficult task, and the hydrogel can’t remain on the press for fear of drying out. It also requires low tension, because any amount of tension may stretch the material out of tolerances. All of this complexity adds cost into the converting process, and hydrogel isn’t a cheap material to begin with.

- Expensive

Hydrogel is more expensive than cloth wound dressings. It has a high Minimum Order Quantity (MOQ), meaning there’s a minimum amount you must order before suppliers allow you to make a purchase.

However, if you’re hoping to find a converter to cut and process it, Strouse can help provide hydrogel samples for potential parts.

Hydrogel is a temperamental, expensive material, albeit with a high potential for wound care, yet you should also know that it must be packaged and shipped carefully.

#3: HOW DO YOU PLAN ON PACKAGING YOUR HYDROGEL?

There are multiple methods of sealing hydrogel depending on if the gel is in sheet or amorphous form.

Amorphous hydrogel comes in tubes for easy application, which makes packaging simple as long as its tubes are kept airtight. On the other hand, sheet hydrogel is heat sealed to preserve moisture before it reaches the client.

After the hydrogel has been processed, many converters use heat sealing to prevent the product from drying out. Heat sealing often uses PET (polyethylene terephthalate) material, which is placed on either side and then heated.

If the sealing heat runs too cold or fast, the package fails to seal, and the hydrogel dries out.

Worried about losing your pristine hydrogel parts? You can save time and guarantee less material waste by running a hydrogel 1-pass production.

#4: WHO ARE SOME OF THE BEST HYDROGEL SUPPLIERS?

If you're planning on using hydrogel, you'll want to buy it from a reputable supplier.

These are our most-used hydrogel suppliers throughout the years:

- Axelgaard

Axelgaard has processed different hydrogels, electrodes, and other specialty products for years. They're one of the first companies we think of when it comes to buying quality hydrogel.

- Sekisui America Corporation

Sekisui America Corporation supplies hydrogel for various purposes, offering a range of conductive options for electrodes or other medical devices. They also deal with thermoplastics, packaging tapes, and foams.

Should I Buy Hydrogel?

Hydrogel shouldn’t be selected on a whim because it’s a niche, expensive, and hard-to-process material.

Depending on your intended purpose, companies often process hydrogel through converters, who cut it down to an exact size until it’s easily accessible for application needs.

If you deal with similar-sized injuries or the wounds you see often occur in the same places, you can request a quote for custom hydrogel parts to spend less time worrying and more time teaching your team how to become hydrogel experts in their field.

Hydrogel applications are a rapidly expanding, innovative wound care solution. If it sounds like the perfect answer to a problem that you’re facing, hydrogel might be your ideal option.

And before you run off to buy some hydrogel and ultimately end up with a gooey mess, check out how partnering with a converter could save your project:

%20(1)-min%20(1).png?width=290&name=Untitled%20(52)%20(1)-min%20(1).png)